The provincial government has indicated it views technological maturity as the path forward for NB manufacturing. The recent throne speech observed that NB manufacturers are embracing technology in new ways and that "automation, artificial intelligence and robotics are fundamental pathways to addressing looming demographic and labour force challenges" in our province. So where are NB manufacturers currently positioned on that pathway?

On November 27, Martin Davis of DUNELM Associates joined Dr. Herb Emery to discuss how NB manufacturers are doing in their drive towards Industry 4.0. The webinar gave a first look at data from a survey instrument built from Martin Davis’s 6-dimension model describing the path to Industry 4.0. The survey is meant to gauge the overall climate of manufacturing in NB and inform future policy decisions by identifying manufacturing strengths and opportunities.

Industry 4.0 relates to the use of cyber-physical systems, strategies and processes to improve industrial productivity, capability and performance. Industry 4.0 is about more than having the latest technologies – it’s a philosophy and strategy for approaching industrial processes that revolves around using data to make the right decisions.

The survey is built around six dimensions described in Davis’ Industry 4.0 Maturity Model:

Preliminary findings

We should caution that these initial results are based on a relatively small pool of responses primarily from medium to large manufacturers, and thus the preliminary results discussed in the webinar may show an “upward bias” to suggest NB’s manufacturers overall are more advanced on the Industry 4.0 scale than they really are. In other work we determined that half of the province’s 1200 manufacturers did not have an active website. Eighty percent of manufacturers in the province have 20 employees or fewer, and these small firms only account for 20 percent of total employment in manufacturing. Our results likely give us a reasonable picture of the technological maturity of the smaller number of medium and large manufacturers that account for 80 percent of the sector’s total employment.

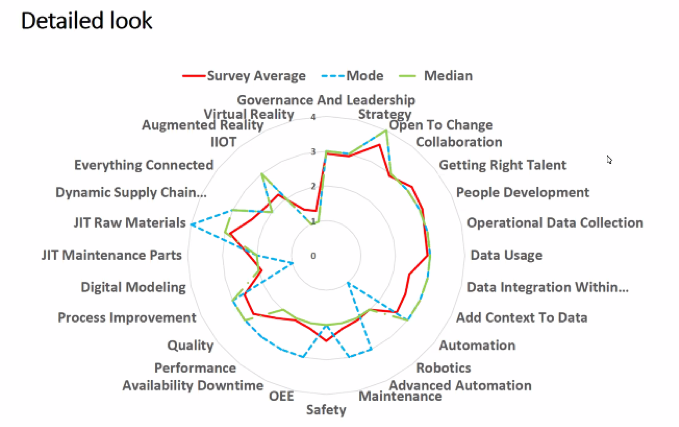

The above chart describes how leaders of manufacturing firms rated their organizations on a scale of 1 (entry level) to 4 (advanced). The results point to an obvious weakness in technology among NB manufacturers. Meanwhile, manufacturers showed moderate scores in data and information, manufacturing efficiency, and leadership and people. In the webinar, Davis noted that firms can achieve a certain amount of manufacturing efficiency without advanced technology, meaning firms can reach an intermediate level in that area without high-cost technological investments. He added, however, that advanced technology becomes required to progress past a certain level in manufacturing efficiency.

A closer look are areas of strength (and weakness) reveals a few things. First, firm “Openness” was surprisingly high – what is unclear is whether this openness is a reflection of leadership or company culture. Having leadership open to pursuing technological maturity is essential, but a firm-wide culture open to change is also necessary for any advances to be successful.

Adoption of VR and AR were very low, but perhaps these areas should be on NB firms’ radar. Right here in our province, for example, Kognitiv Spark produces industrial grade AR support tools, a technology that has applications for manufacturing such as allowing remote repairs to occur when local workers don’t have the expertise for certain equipment.

A few other themes that emerged from the presentation:

Want to learn more?

To learn more about Martin Davis's other recent work on Industry 4.0 and how it relates to our manufacturing sector in NB, check out the latest TechTalks Podcast episode. Host Cathy Simpson, CEO of TechImpact, chats with Martin Davis to unpack Industry 4.0 terminology, including the Industrial Internet of Things (IIoT), machine learning, AI, and advanced manufacturing.

Check out the show notes on the TechImpact website.

Dr. Sarah McRae is a postdoctoral fellow at the University of New Brunswick and a member of the JDI Roundtable research team.

The JDI Roundtable on Manufacturing Competitiveness in New Brunswick is an independent research program made possible through the generosity of J.D. Irving, Ltd. The funding supports arms-length research conducted at UNB.