World-class facilities

Our services and research

Biotech laboratory

Since our inception, scientists in the Biotechnology lab have been conducting research and industrial testing on the role of fungi in the decay of wood and wood products; the deterioration of wood coatings and finishes; and, more recently, the testing of new wood preservatives for resistance to decay.

In the coming years, with the help of a new research scientist, the lab will extend research and testing to include the role of insects in the deterioration of wood and changes in wood quality.

The lab contains all of the equipment necessary for microbiological studies, including an autoclave, two laminar flow hoods, and a walk-in temperature/humidity-controlled incubator.

Chemistry laboratory

Our chemistry laboratory is equipped to evaluate some of the chemical characteristics of wood, wood adhesives and finishes, and resin synthesis and characterization. Chemical and enzymatic treatments to enhance the physical and mechanical properties of non-wood natural fibres are also conducted at WSTC laboratory.

The laboratory is also engaged in routine water analyses such as pH, conductivity/TDS/hardness/alkalinity and chloride determination. Some of the available pieces of equipment include:

- Benchtop and handheld pH meters

- Brookfield viscometer

- Conductivity/TDS/salinity/temperature meter

- Differential scanning calorimeter

We also partner with the Faculty of Forestry & Environmental Management and other departments in the university for further characterization of wood, non-woofibresral fibers, polymer and biofuels.

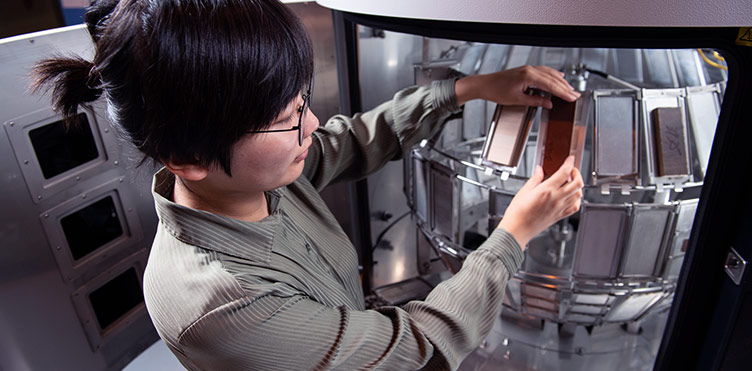

Composite laboratory

The composite laboratory was created to help develop and improve existing industrial manufacturing processes for wood composite products. Research and development activities include evaluating innovative wood adhesives and additives for use in wood composites.

Having this integrated facility places UNB among a small elite group of North American universities that possess such research capabilities. The facility is considered essential for UNB to continue to play an important role in assisting the wood composite industry with improving existing processes and developing of new processes and innovative products. The equipment available in the laboratory includes:

- Blender with spinning disc atomizers

- Diffenbacher laboratory hot press

- Mat-forming line

- Small stainless blender

Full-scale mechanical testing

WSTC's full-scale mechanical testing laboratory boasts numerous machines capable of testing a wide variety of products including lumber, oriented-strand board (OSB), I-joists and utility poles.

The laboratory also includes facilities to prepare the necessary test specimens to meet accredited test standards and custom test jigs for novel products.

Prototyping and pilot scale laboratory

We are often requested to provide proof of concept work for its clientele.

Our prototyping laboratory is equipped with a production finger joint line for fabricating prototype finger jointed wood products, a lumber machine stress rating system for grade yield studies, glulaminating press for fabrication of panel and beam products and full-scale test gear to evaluate prototypes produced.

This laboratory is a place for testing prototype equipment and processes as well.

Wood technology and quality laboratory

The quality laboratory was established to evaluate wood from the microscopic cellular level to the macroscopic lumber level.

The research deliverables contribute to improvement in silvicultural practices, wood-based composites, engineered wood products, timber engineering design and biofuels.